6/21

Plant-Based Leaders | SmartSolve

An innovative, patented plant-based packaging material from SmartSolve has the potential to replace a share of traditional, single-use plastics on grocery store shelves today.

The foundation of SmartSolve packaging is crafted with bio-based materials, consisting primarily of wood pulp from Forest Stewardship Council (FSC) Certified forests combined with other inert ingredients.

And when that packaging is ready for disposal?

Just add water.

That’s right, just water.

When the material comes in contact with H2O, the inert content dissolves and the wood pulp fibers pull apart into tiny microfibers. Then, naturally occurring microorganisms and bacteria, which are found in abundance throughout the earth, break down the remaining wood pulp fibers, allowing the package to fully biodegrade, leaving zero waste.

As a result, SmartSolve’s packaging can be marketed as “drain safe” or even flushable as validated by the INDA/EDANA flushability protocols (FG501-FG504, FG507).

For those who think this is too good to be true, don’t let your hope dissolve. SmartSolve’s first generation of packaging technology has already hit the market with a number of examples in the personal care sector. Several of these products are a viral sensation as SmartSolve customers have gained millions of impressions on Instagram and TikTok by simply showing the material dissolve.

New Patented Packaging Tech

“In February, we were awarded a significant patent,” explains Jonathan Jakubowski, President of SmartSolve. “And that patent is for a combination of water-soluble paper and any biopolymeric coating.”

The result is what many consumers have long desired: worry-free packaging.

“When we combine biopolymers with water-soluble paper, we can deliver a zero-waste packaging solution which is also bio-based,” said Jonathan.

The ability to disperse or dissolve upon contact with water makes this packaging extraordinary.

“When we combine biopolymers with water-soluble paper, we can deliver a zero-waste packaging solution which is also bio-based.”

“Our product has a really unique value proposition in that it’s flushable and drain-safe. When we combine flushability, composability, biodegradability, and biobased content, we are delivering a truly unique value proposition with this family of patent-protected technologies.”

Opportunity Up and Down the Grocery Aisle

“We’re going to market early next year, creating packaging for foods that have low barrier requirements and which are shelf stable,” said Ashleigh Hotz, the company’s Director of Sales. “Think powders or dry granular foods.”

Imagine a walk through the grocery store. Then, consider just the foods that are often packaged with an exterior cardboard box and then a plastic bag inside: granola bars, cereal, pasta, rice, oatmeal, hot chocolate, mac and cheese, cake mixes, spices, seasonings, and many confectioneries, like hard candies – to name just a few.

“So many companies have over-engineered their packaging, with a thousand years of life, yet by the nature of their products, they do not require such significant barrier properties,” said Jonathan.

SmartSolve claims they can help those companies skip a generation of packaging technology.

“We can provide brands a game changer, allowing them to market to their customers on the sustainability front in ways that have already proven wildly successful with our first generation of products,” said Ashleigh.

SmartSolve has three main product lines: uncoated paper stock, pressure sensitive label stock, and pouch stock used in flexible packaging.

The pouch stock has incredible claims, such as zero waste, flushable, biodegradable, recyclable, non-toxic to fish, and free from microplastics, proposition 65 chemicals, PFAS, BPA, and Phthalates. The new patented technology will add to these claims with compostability and entirely bio-based.

Sustainability Standards and Testing

SmartSolve is aware that such extraordinary claims require extraordinary evidence, as famed scientist Carl Sagan, and others, have said.

“Not only do we want to make a positive impact, we want to be honest and straightforward in the way that we make claims.”

“Not only do we want to make a positive impact, we want to be honest and straightforward in the way that we make claims,” explains Jonathan.

The company intentionally relies on respected third-party standards and certifications when making such statements.

“We’ve spent a lot of time, treasure, and talent investigating relevant certifications that apply to our materials, their various formats, and where and how they’re used,” said Jonathan.

SmartSolve takes seriously the risk of “greenwashing” accusations – both for itself and its customers.

Take just one case at least partially related to SmartSolve. In November, the EPA was petitioned by nonprofits to take action against the plastic film of detergent pods, a product used by many consumers in their dishwashers and washing machines. The petition argued that contrary to advertising, the petroleum-based plastic polyvinyl alcohol, also known as PVA or PVOH, which forms the pod, does not completely break down in water, but rather 75% remains intact. SmartSolve’s first generation of technology continues to depend upon PVOH technology. However, it reduces PVOH content by combining it with water-soluble paper while also using the most biodegradable version of PVOH which meets OECD 301B’s highest standards for ready biodegradation.

SmartSolve’s next generation of packaging eliminates PVOH and even offers companies the ability to print on individual pod packaging, offering an opportunity for last-look branding or even safety warnings.

“Consumer awareness about false sustainability claims continues to increase, especially with the younger generations, and companies are being held accountable for claims that can’t actually be fulfilled,” said Ashleigh.

And SmartSolve works with downstream brands and clients closely on these matters.

“We communicate intensively with our customers from the beginning, starting with the process of ideation through delivery of these technologies to market. We want to be sure that when sustainability claims are made about our products, they are backed up with certifications with demonstrable evidence,” said Jonathan.

Sustainable Solutions for Oceans and Waterways, from our Forests

That means this new, sustainable family of materials not only offers brands a better choice that consumers will appreciate when it’s time for disposal, but the innovation, if widely adopted, could help reduce the impact of some single-use plastics on our oceans and waterways.

“I do a lot of work in Guatemala with the nonprofit I founded that helps disadvantaged youth,” said Jonathan. “You’ll often see in the streams and creeks of these faraway places, all sorts of plastic packaging and snack packaging. And without a good municipal waste system and a process of collection, it just invades that environment and remains there forever.”

He hopes his company’s biobased innovations can help address such plastics pollution worldwide.

SmartSolve’s new patented technology is biobased and as previously noted pulp that makes the water-soluble paper is sourced from FSC certified forests, another globally recognized third party in the sustainability space.

That means the forest-based materials “are harvested responsibly so there is no net loss of forest over time,” per the FSC.

All FSC-certified materials, including reclaimed materials, are identified and tracked during the manufacturing and distribution processes.

Going to Market with Partners – A Case Study

SmartSolve already has impressive products on the market. PLUS body wash went viral across TikTok, Instagram, and other social media in large part because of SmartSolve packaging.

“Less waste, more magic,” is the tagline PLUS uses and the magic they refer to is their dissolvable packaging which vanishes down the drain, all supplied by SmartSolve.

Even the ink is bio-renewable and FDA approved as the PLUS website explains.

When PLUS was first developing this product, they knew they wanted bio-renewable ink. And SmartSolve was instrumental in building a coalition of business partners to deliver on their vision, including helping to source the ink provider.

As a result, PLUS was named a “Best Invention” of 2022 by Time Magazine and was picked up by Target.

The Next Generation of Packaging

SmartSolve expects to go to market with its new generation of patented packaging in the first quarter of 2024 and hopes to deliver the same buzz for its partners.

“Over the next six months, we’re offering a few select companies privileged access to our patent that are interested in developing a custom coating which meets their barrier specification requirements,” said Ashleigh.

SmartSolve’s lab is up and running for that purpose. It allows the company to measure everything from moisture barrier, to adhesion release, to base weight. The lab also examines the chemical and physical properties of different substrates, as it works to meet partners’ needs.

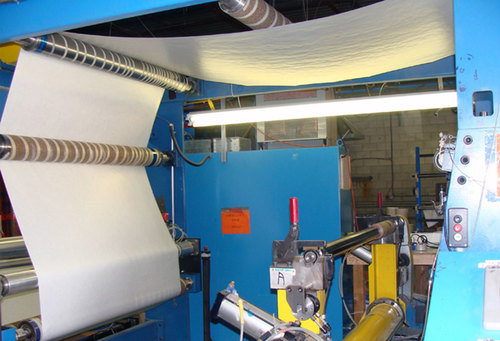

There is also a manufacturing arena with an industrial coater, allowing SmartSolve to go from the lab where they are creating polymers right to the paper for testing.

“That trial coater enables the creation of rolls of product that are several thousand feet in length by 24-inch width, so that customers can take that back and test it on their own converting equipment,” said Jonathan.

Commercial, larger-run, long-scale printing is also available next door at the facilities of SmartSolve’s parent company, CMC.

And while dry goods food packaging that have lower barrier requirements is the first step, there is more to come.

Jonathan describes the company’s strategy in both manufacturing and science as, “Crawl, walk, run.”

“As the technology matures, the question is going to shift to ‘How much barrier can we create?’ and still meet our environmental and water solubility and dispersion claims,” said Jonathan.

SmartSolve’s R&D team is already hard at work on those questions and innovations.

PBPC: Bringing Industry Recognition

Yet to meet the company’s goals more needs to be done to drive interest in the broader product category. That’s where the Plant Based Product Council (PBPC) has thrived.

“PBPC is driving awareness and familiarity around an industry that most people have no idea about. That is creating the rising tide that is lifting all boats in the biobased materials space.”

“PBPC is driving awareness and familiarity around an industry that most people have no idea about. That is creating the rising tide that is lifting all boats in the biobased materials space,” said Jonathan.

Jonathan and SmartSolve are eager to help solve the environmental challenges ahead.

“SmartSolve and our PBPC peers represent real solutions to serious global environmental concerns. We are incredibly grateful to be among this group, working on products that can change the face of the planet for the better,” said Jonathan.

Join our growing group of plant-based leaders working toward a more sustainable economy. Learn more about the benefits of PBPC membership.