7/8

Plant-Based Leaders | Loliware

For this edition of Plant-Based Leaders, we interviewed Sea Briganti, Founder and CEO of Loliware, and Catherine Greener, Chief Impact Officer. Loliware is replacing petroleum-based plastics with seaweed-derived resins that are always “Designed to Disappear.” Their first products, an award-winning seaweed-based straw portfolio and a new cutlery set, are already transforming the future of sustainable products, and they’ve just partnered with a major distributor to offer seaweed-based, drop-in resins.

Sea Briganti, Founder and CEO, Loliware

Catherine Greener, Chief Impact Officer, Loliware

Q

What inspired you to start Loliware?

A

Sea: The inspiration for Loliware began over 14 years ago, at the intersection of industrial design, engineering, and materials science. After graduating at the top of my class in industrial design and engineering, my thesis — named Thesis of the Year — was featured in Fast Company on the day I graduated. That moment affirmed for me that breakthrough ideas rooted in science and technology can reshape the future, and I was inspired to see where that convergence would lead me.

Rather than follow a conventional career path, I used that early momentum to co-found The Way We See the World, a product design collective that set out to reimagine packaging and CPG — using competitions and experimental projects as test beds for radically new approaches.

Those early explorations laid the foundation for my founding of Loliware: a company driven by the conviction that materials can go beyond performance to become catalysts for systemic change. By harnessing the power of AI and seaweed-materials science, Loliware is pioneering a future where materials don’t just replace plastic — they restore ecosystems, capture carbon, create economies, and redefine our relationship with the natural world.

Q

When did seaweed come into the picture?

A

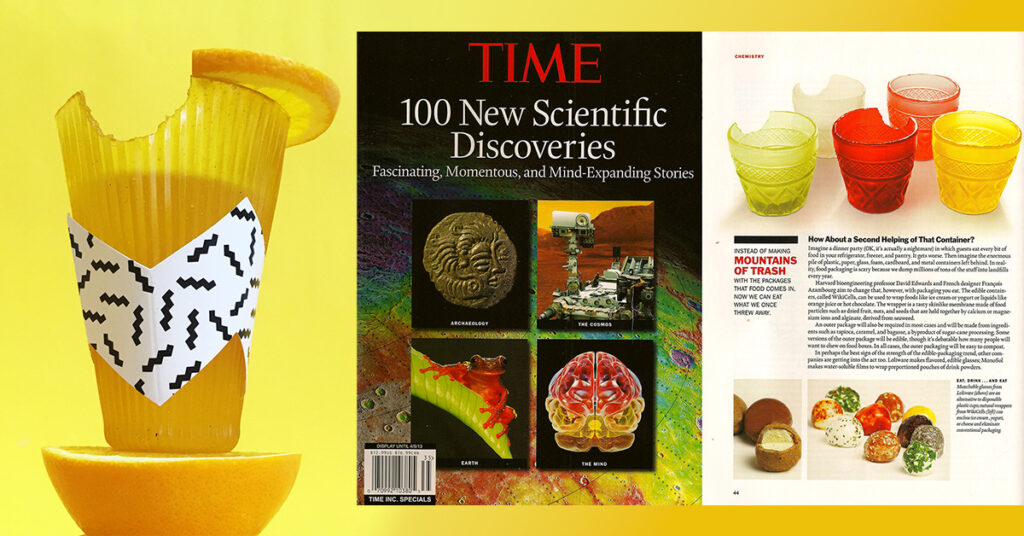

Sea: In 2012, something shifted. PepsiCo (Frito-Lay) had just launched its first compostable chip bag, but the market’s backlash revealed a critical gap between sustainable innovation and user experience. We saw an opportunity and sent an email directly to Indra Nooyi, then CEO of PepsiCo, proposing a bold idea: What if packaging could be made from seaweed — and what if you could eat it?

To our surprise, she and her team responded within an hour and invited us to present to their CTO at their R&D center. After our presentation, we were offered a contract to collaborate on breakthrough innovation pipelines as “intrapreneurs.” That experience opened the door to further collaborations with major players like Nestlé and Pernod Ricard.

The more I explored seaweed, the more I realized its unparalleled potential to replace packaging and single-use products. Its naturally compostable, rapidly renewable, carbon-negative, and regenerative qualities make it an ideal material to transform how we think about the future of materials.

Q

How did you scale the product, and what led to the straw?

A

Sea: After raising our first $1 million, we moved production to Mexico and began manufacturing the first generation of our seaweed-based edible cups. While they captured imaginations around the world, they were still cost-prohibitive — unable to compete with plastic on price or scalability. I recognized that to create true impact, our materials had to advance, be more scalable to reduce COGs, and compatible with existing plastics manufacturing infrastructure.

Then, in 2019, a cultural tipping point arrived. The viral video of a sea turtle with a plastic straw lodged in its nose sparked global outrage. California led with plastic straw bans, and soon over 30 countries followed. The world was finally ready to act — and we seized the moment. We launched the world’s first seaweed-based straw, designed to perform like plastic but without the environmental cost. I raised an additional $6 million to build pilot production in Missouri, and since then, we’ve produced millions of straws. This milestone proved that regenerative materials can scale globally — and that seaweed has the potential to lead a new era of materials innovation.

Q

In April you announced a major partnership with Entec (Ravago), the largest resin distributor in North America. What does this partnership mean for you?

A

Sea: This partnership with Entec (Ravago) is a game-changer. As a true leader and innovator in this space, they distribute billions of pounds of resin annually — and now, for the first time, seaweed-based resin is part of that established system.

What makes this even more powerful is the caliber of the Entec team. We’re collaborating with the best of the best — pioneers in manufacturing, scale, and advanced materials. Their deep expertise and commitment to pushing boundaries make them the ideal partner to accelerate bioresin technologies.

By embedding our material into Entec’s global supply chains, we’re removing barriers to adoption and enabling manufacturers to transition to environmentally superior alternatives without operational disruption.

Our vision is to make the shift to seaweed-based resin as seamless as swapping out a printer cartridge — same performance, same reliability, but with a dramatically better carbon and environmental footprint. The easier we make that transition, the faster we scale, and the greater our impact will be.

Q

It sounds like your seaweed resins can be a drop-in material to existing manufacturing systems designed for traditional plastics. Is that correct?

A

Sea: Yes — SEA Tech® resins are designed as true 1:1 drop-in replacements for conventional plastics. They offer excellent mechanical strength, processability, and a naturally superior degradation profile. Customers can expect consistency and performance across applications.

Catherine: The beauty of our approach is that no major capital investment is required. For manufacturers and brands, it’s important to understand that sustainability doesn’t have to compromise function — with SEA Tech®, you get the best of both worlds. When adoption is easy, transformation can happen at scale.

Q

Could you share more about the initiative for a plastic-free Central America and the grant you received from the Subnational Climate Fund?

A

Sea: We were awarded a grant from the Subnational Climate Fund to conduct a feasibility assessment in the region, and while some details are still under wraps, we’re preparing to announce an exciting initiative with the potential to transform Central America’s materials landscape.

What makes this effort truly exciting is that it goes far beyond simply replacing plastic — It’s about catalyzing a new regenerative economy. We’re creating local opportunities for production, licensing, and distribution.

These resins will be supplied directly to local plastics manufacturers, empowering them to produce beautifully designed, high-margin products that are engineered to disappear — advancing both economic resilience and environmental stewardship.

Catherine: And we’re building the entire Loliware ecosystem from the ground up. Upstream, we’re focused on scaling seaweed farming operations to ensure a reliable, regenerative raw material supply. By 2026, our vision is to establish a fully circular model that delivers both economic resilience and environmental impact — precisely where it’s needed most.

Q

You’ve received several awards and developed an impressive array of partnerships, with the likes of Surfrider, Google, and others. How have these shaped your business and outlook?

A

Sea: Partnerships like the one we have with the Surfrider Foundation are essential to our mission. Their Ocean Friendly Restaurants program now includes over 600 establishments, and we’re proud to support it by providing truly ocean-safe alternatives to plastic. It’s a powerful example of how values-aligned collaboration can scale both awareness and real impact.

Winning Google’s Single-Use Plastics Challenge in 2023 was another pivotal milestone. This recognition not only validated the strength of our technology but also led to Loliware becoming part of Google’s global supply chain. As we expand production, Loliware products will be integrated across Google’s campuses worldwide — a powerful signal that regenerative materials are no longer a niche concept, but ready for mainstream adoption at scale.

Q

What other strategic partnerships have you created?

A

Sea: We’ve built a unique collaboration with Chef José Andrés’ restaurants and we also partner with forward-thinking hospitality brands like 1 Hotels, which made the switch to Loliware in 2022. Their composting partner had flagged concerns about other so-called “compostable” products, so they ran independent 60-day degradation tests on our seaweed-based straws. The results were clear: our straws broke down fully into nutrient-rich soil. That level of performance is what secured the partnership — and it’s what sets us apart.

This year, we’re also launching with a few more major hotel groups, including Easton Hotel Group in Canada, a new partner in Japan, and one of the largest global hospitality brands. These partnerships are key to accelerating adoption and demonstrating that seaweed-based materials can meet the highest standards of performance, design, and environmental stewardship.

Catherine: Hospitality has emerged as a strong early market for us. Companies in this sector are deeply motivated to deliver exceptional guest experiences while minimizing waste and environmental impact. Additionally, greater pricing elasticity allows them to adopt premium, future-forward materials that align with their sustainability commitments.

Q

You’re pursuing Oceanic Global’s Blue Standard. Can you tell us more about that and why it matters?

A

Sea: We’ve already earned the Blue Standard certification from Oceanic Global for our finished products, such as our straws, which are verified to be truly plastic-free. It’s a critical validation of our commitment to designing products that are safe for both people and our planet. Now, we’re taking it a step further — Catherine is leading the effort to certify our seaweed-based resin itself, which will further validate the integrity of our materials at the source.

Catherine: The Blue Standard considers the entire product lifecycle — from how a material is sourced to what happens at its end of use. That phrase is important: end of use rather than end of life. Our materials don’t just disappear — they deliver environmental benefits by breaking down into nutrient-rich compost. Pursuing this certification reinforces our systems-based approach to regenerative materials and ensures we’re meeting the highest bar for environmental accountability.

Q

Your products are seaweed-based, but you are equally attentive to your packaging. How does that fit into this standard?

A

Sea: Sustainability doesn’t end with the product — it informs every aspect of how we operate, right down to our packaging. All of our packaging is 100% paper-based: we use recycled paper wrappers printed with algae ink, wax-coated paper cartons that are entirely plastic-free, and recycled cardboard shipping boxes.

Every packaging choice reflects our mission and aligns with rigorous frameworks like Oceanic Global’s Blue Standard, which takes a systems-level approach to true environmental impact.

Q

Mars partnered with Unreasonable Group to launch Unreasonable Food, a program supporting sustainability goals. Loliware was chosen to participate. Can you tell us about that?

A

Sea: We joined the Unreasonable Food Cohort in mid-2024, an incredible opportunity to collaborate with global leaders dedicated to transforming the future of food and packaging. Mars, in particular, has shown bold leadership in this space. Their deep commitment to achieving Net Zero — supported by ambitious targets for packaging innovation and supply chain decarbonization — makes them an ideal partner for Loliware. Together, we’re working to accelerate a future where regenerative materials become the new standard.

Catherine: Loliware is uniquely positioned to support both sides of Mars’ climate goals. On one hand, our verified low-carbon products directly contribute to supply chain decarbonization. On the other hand, our compostable packaging helps them meet strict end-of-use standards.

Q

What is your company’s relationship with PBPC, and what value do you see or hope to gain?

A

Sea: As a founding member of the Plant Based Products Council (PBPC), I’m proud to be part of a coalition that is actively shaping the future of materials. PBPC is a true kindred spirit — deeply committed to innovation, grounded in science and policy, and focused on accelerating the transition away from fossil fuel–based plastics.

What truly sets PBPC apart is its visionary leadership on policy and regulation. Their work in Washington, D.C., and on the global stage is critical — creating the frameworks that enable biobased materials to scale responsibly and effectively. I see our role as both contributor and beneficiary: helping to drive progress while learning from an inspiring community of leaders and changemakers.

PBPC’s work in Washington, D.C., and on the global stage is critical — creating the frameworks that enable biobased materials to scale responsibly and effectively.

Join our growing group of plant-based leaders working toward a more sustainable economy. Learn more about the benefits of PBPC membership.