11/4

Plant-Based Leaders | Brent H. Shanks

Green Chemistry: The Art of Replacement

Anson Marston Distinguished Professor in Engineering

Mike and Jean Steffenson Faculty Chair, Chemical & Biological Engineering

Director, Center for Biorenewable Chemicals (CBiRC)

Iowa State University

The goal of green chemistry is simple enough: replace many of the world’s petroleum-based consumer and industrial products with plant-based versions. But from start to finish, the process requires a veritable army of unique specialists:

- Scientists must create new plant-based molecules.

- Engineers must effectively scale up that process to mass production in giant fermenters.

- Entrepreneurs must bring the product to commercial markets.

- And thought leaders must help shape the broader environment.

Or, one could simply call Dr. Brent Shanks.

With more than two decades of experience in the field of green chemistry at Iowa State University and more than a hundred published articles, Dr. Shanks is doing it all: teaching, making discoveries in the lab, founding start-ups, and driving those start-ups’ commercial success.

As a result, he offers a horizon-to-horizon perspective. Dr. Shanks is well-placed to identify and help solve many of the industry’s most pressing challenges, often working hand-in-hand with other leaders across government and industry.

“Platform Molecules”

Dr. Shanks specializes in turning biomass, such as corn or vegetable oil, into new molecules that can replace petroleum-derived sources. Much of his work focuses on catalysts, the accelerants that convert biomass found in nature into the new, intended molecules.

But rather than seek one molecule or one commercial product at a time, the Shanks Method is to seek a “platform molecule.”

“I am always asking, how can we leverage the knowledge that we’re developing to not only make a specific desired product, but one that can then be leveraged further to make other products as well?” explained Dr. Shanks.

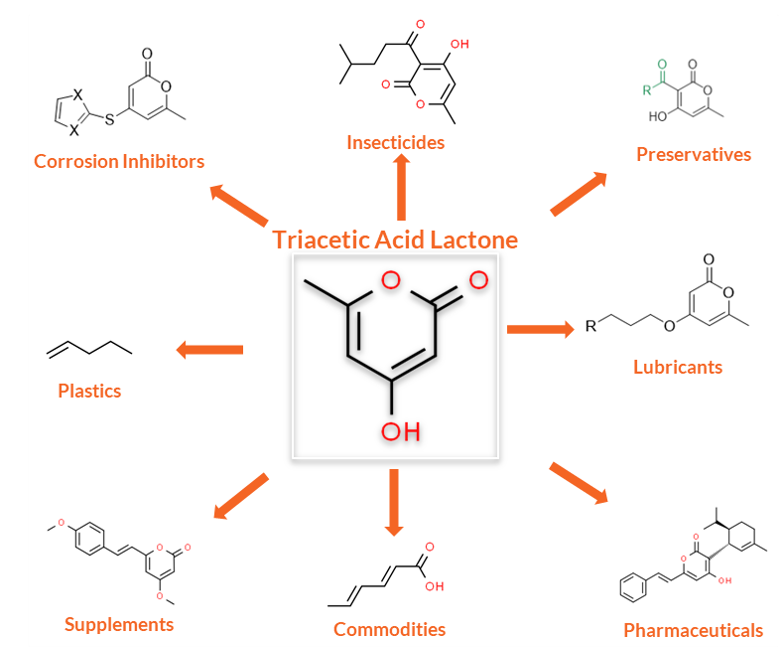

Take, for example, Dr. Shanks’ efforts in the lab to create simple, cost-efficient methods to diversify products from triacetic acid lactone, or TAL.

“TAL can be produced from fermentation,” he said. “And it is a perfect example of a platform molecule as it allows you to convert it further to numerous other products. One product that you can convert it to is pogostone, a bio-based repellent and insecticide,” he added.

Start-up Entrepreneur

Such a bio-insecticide can target mosquitos, ticks, cockroaches, termites, and crop pests, protecting humans, homes, and food crops through more natural and more effective repellents, creating a powerful new entrant in the $25 billion global market.

“What’s interesting about this molecule is that it is a completely different molecule than existing insecticides,” he added. “There are basically three categories of insecticides, each has been around for a long time, and insects are starting to develop resistance to them. We have something completely new.”

He noted, “It has repellency properties like DEET, but it also has an insecticidal activity,” which means it could be used on human skin as well as in homes, gardens, and crop fields. Dr. Shanks has teamed up with three other experts in the field to launch the start-up Pyrone Systems and take their bio-insecticide to market.

And Pyrone Systems is creating this new molecule from vegetable oil, which would come, for example, from the waste streams of food processing.

But TAL’s versatility only begins with the bio-insecticide, pogostone. As a green platform molecule, TAL has a bright future ahead of it. With the help of different catalysts and processes to make additional product molecules, TAL could also become the key ingredient in many other items like organic corrosion inhibitors and lubricants, two other categories of products that are often derived from petroleum.

Yet TAL is only one of the plant-based ingredients Dr. Shanks is building and Pyrone is only one of his start-up ventures.

Seeking Scale to Drive Opportunities

Even as start-ups increasingly seek to displace petroleum products, green chemistry companies have traditionally started at a deep disadvantage.

Dr. Shanks has seen that disadvantage first-hand, having once worked for Shell. “The petrochemical industry is very mature. They already possess the knowledge required to scale up – to take a product from the lab, to a pilot program, to commercial scale,” he explained.

Given the petrochemical industry’s century-plus in existence, the green chemistry industry is still in its infancy by comparison.

“If the petrochemical industry has a new development in the lab, they know exactly which experiments are needed to reach pilot scale and then go to commercial scale, and they can often do it in three scales with existing infrastructure,” said Dr. Shanks. “Because we are new, green chemistry has fewer models to work from.”

That means green chemistry requires more time and resources to reach commercialization and is in dire need of more infrastructure.

And while Dr. Shanks and his team are taking Pyrone Systems through the scales toward commercialization, he is also working on industry-wide solutions that will help support other green chemistry companies working to scale up their own inventions.

Green Chemistry Companies Wanted for Unique National Program

“I would say the U.S. leads the world in synthetic biology and biotechnology at the lab scale. But we have a weakness concerning how we take those technologies and translate them to commercial reality. That’s the scale-up piece,” he explained. “That includes both infrastructure development and capability development, in terms of workforce.”

Take infrastructure first.

The 50,000-liter fermenters required to bring a new biotechnology to commercial scale are incredibly expensive – certainly out of reach for most start-ups. “We don’t really have that kind of capability commonly available in the U.S. and that is a significant bottleneck,” he said.

But Dr. Shanks has been working on a solution.

“This area is ripe for public-private partnerships supported by the federal government, which can deliver this kind of scale-up. It would really help move the industry forward,” he added.

Dr. Shanks is working with the BioMADE program, a bio-manufacturing innovation group that is a public-private partnership run by the U.S. Department of Defense. Dr. Shanks is helping the BioMADE team consider how to tackle some of the industry’s leading challenges.

“I am keenly interested in helping them define a strategy for how to effectively fill this scale up weakness that we have in the United States,” he said.

BioMADE is also working to improve national workforce capabilities to ensure that U.S. workers have the expertise and skillsets to help companies succeed in this space. And while Dr. Shanks has already encouraged his corporate contacts to participate, he is eager to recruit additional collaborators.

“We would love for even more companies to get engaged. The more companies we have, the better the outcome because each brings clear knowledge of what’s required to ensure we build a program that is commercially relevant,” he added.

“Quite candidly, most academics and national lab folks just don’t have the experience to deliver that viewpoint,” he explained. “BioMADE is very open and wants that input from everyone – from early-stage start-ups to larger companies that are already commercially successful, perhaps especially the latter who have so much experience to share.”

Praise for the Biden Administration

But BioMADE is not operating in a vacuum. In September, the Biden Administration released an “Executive Order on Advancing Biotechnology and Biomanufacturing.” Dr. Shanks believes it will be a critical tool to assist the industry.

Among its leading priorities are: bolstering and coordinating federal investment in biotechnology and biomanufacturing R&D, improving and expanding domestic biomanufacturing production capacity and processes while increasing pilot and prototype efforts, and boosting sustainable biomass production.

“The executive order speaks specifically to capital infrastructure, so it’s a beautiful connection to BioMADE’s current efforts. Things are really coming together for the industry,” Dr. Shanks said.

PBPC as Policy Driver

As an advisory board member at the Plant Based Products Council (PBPC), Dr. Shanks recognizes the power of alliances like BioMADE and PBPC to advance public policy and raise public awareness.

“To move this industry forward, we need consumer demand and further improvement of our technological infrastructure. The latter will be driven in part by government policy,” he said. “PBPC helps inform policymakers, making sure they truly understand the industry’s needs.”

With the many hats he wears across the industry, Dr. Shanks often serves as a key node in the industry’s network, bringing together disparate industry elements.

He believes PBPC fulfills a similar and equally crucial role, “PBPC is a convener and also a bridge, helping connect different groups and the government so everyone can understand what’s happening in the space and then ensuring that we are working together to advance our goals.”