4/9

Plant-Based Leaders | BioLogiQ

For this edition of Plant-Based Leaders, we interviewed Steven Sherman, the CEO of PBPC member BioLogiQ, a bioplastics leader with a footprint in both the U.S. and Asia.

Q

Tell us a bit about the founding of BioLogiQ and its mission.

A

We were founded to reduce the accumulation of plastic pollution on our planet, and that mission is right there in our name. We leverage natural systems, that’s the “bio,” and we do so in pragmatic and realistic ways, that’s the “logic,” and we deliver unique innovation, the “iQ.”

Our founder, Brad LaPray, started using products from the waste stream of potato processing and then continued to innovate with corn products. After considerable development of the technology, we launched commercially in 2017.

Q

This isn’t your first start-up. What attracted you to the plant-based space?

A

My whole career has been with innovative, industry-leading and paradigm-breaking technology companies. I enjoy the challenge of innovation, and I enjoy growing teams and individuals as well as seeing the technology I develop touch markets and consumers. But with BioLogiQ, the added dimension of helping the planet is very compelling. It’s demanding work, but also satisfying when you know the benefits of your success equate to benefits to the environment and society.

Q

Many of the leaders in this sector are building their first company. What advice do you have for them?

A

To launch a company requires building in assumptions and variables in calculating your strategy. But as you rapidly gain experience and market feedback, you need to review your assumptions and then course correct based on the new information you have plugged in. Sometimes course correction can take more courage than what was required when embarking on the journey in the first place. Accordingly, “failing fast” enables rapid iteration, and that provides the data you need to turn your early assumptions into facts and make those inevitable corrections and adjustments.

Q

Last September, you spoke at a Research, Innovation, & Engineered Fabrics Conference on biobased resins outperforming plastics. When you enter a room like that – filled with industry insiders, many of whom have done something one way for a very long time – how do you make your case?

A

First of all, when it comes to “sustainability solutions” I think a healthy skepticism is a good thing. That being said, entrenched, established paradigms are hard for all of us to break through. Most would rather interact passively or be reactive to existing standards, methods, and thinking instead of pushing up against them. Breaking paradigms becomes more likely when existing methods fail to address a problem that has become conspicuous and damaging.

The accumulation of plastic pollution has become a large enough problem that most people no matter their industry or past practice are willing to sincerely contemplate BioLogiQ’s offerings and value propositions.

As sustainability becomes a priority and our products are better understood, our products become even more attractive. When we share our data, patents, third party test results, and peer reviewed published materials, we have a very compelling story and we get very active engagement.

Q

The company utilizes a number of different sustainable feedstocks – corn, cassava, potatoes and more – what’s the benefit to having so many different resources available?

A

In the right hands, each of these industrial feedstocks offers different functional properties when you’re creating new products like ours. Our expert team brings a comprehensive understanding of those different feedstocks and what they offer. Then we utilize that understanding in our selection and mixing processes to deliver a range of products with various features, for example, offering different levels of rigidity, elasticity, or tensile strength. By offering a broad range of functional properties, our materials are more likely to help society decouple from fossil fuel feedstocks.

Q

While BioLogiQ started out in rural Idaho, you now have a footprint in Asia. Why did you choose to expand into that market? Can you talk about the increase in global demand that you’re seeing?

A

We see tremendous need as well as opportunity in Asia for our products. Adding our products to applications can help reduce the pollution from plastic that is not recycled, and more importantly, from the plastic that is not collected. It’s the uncollected plastic waste that turns into plastic pollution. With one-third of the planet’s population not even having regular garbage collection, it is important to have our solution in place all over the globe.

Q

For your U.S. operations, you source all of your feedstocks domestically, correct?

A

Yes, we’re always focused on locally sourced materials. And in the U.S., the result is an important relationship with U.S. farmers. We believe it’s vital to support rural communities and our farmers. And we are working more closely with those communities on both the business aspects and also with sustainability issues. But these kinds of discussions with growers can’t be one sided demands, but rather require we focus on real dialogue to find mutually beneficial solutions. Pursuing improved sustainability will always require trade-offs, so we have to make sure to carefully weigh, consider, and reconsider our operating assumptions about feedstocks with our farming partners.

Q

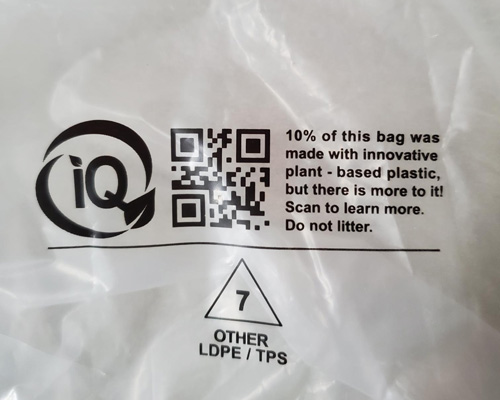

There’s a lot of consumer confusion when it comes to plant-based plastics, biodegradation, compostability, and how to properly dispose of packaging. You’re working on a B2C labeling program, can you talk about how that helps you and your clients address this issue for consumers?

A

With so many different options and claims out there for consumers, it’s very confusing, so our efforts center around helping consumers better understand the real benefits of products versus the imagined benefits. We try to be simple and clear. Our educational materials for our downstream customers create opportunities to help better inform the public, and they in turn can feel good about purchasing the products that BioLogiQ enhances.

Q

Your team describes your product NuplastiQ as “carbon neutral at the gate.” What does that mean for downstream business customers?

A

When our clients include a percentage of our resin blends in their current products, it helps those companies reduce their carbon footprint. It is a pound for pound, kilogram for kilogram benefit in their carbon reduction. Choosing to use our products provides manufacturers with a very easy way for brands and manufacturers to meet their environmental goals of reducing virgin fossil-based plastics, reducing the accumulation of plastic pollution, and reducing their carbon footprint all at the same time.

Q

Talk to us a bit about those downstream customers. Are there any industries in particular driving the demand?

A

We have solutions for durable end uses – think pallets, toys, rigid containers, blow molded bottles, etc. – as well as single use products like sandwich bags, food packaging, frozen food bags, cutlery, straws, trash bags, and lip-balm tubes.

We also have solutions that use recycled content and extend the usage of recycled materials in applications.

Q

What priorities do you hope policymakers will consider when working on the next Farm Bill?

A

The Farm Bill is a necessary and essential part of national policy and needs to be renewed. Policymakers need a better overall understanding of what sustainability really means and how agriculture can indeed really help reduce plastic pollution. We believe in supporting our farmers and growers who are so important to our nation’s infrastructure and economy. And plant-based materials only add to the value they bring.

Q

As a new member to PBPC, what attracted you to PBPC? How do you see BioLogiQ and PBPC working together on policy goals or other areas and issues? What goals do you have for your PBPC membership?

A

We see plant-based materials and technologies playing an essential role in sustainability, improving the world for our children and grandchildren, and working with like-minded groups can only help us get there quicker.

It is becoming more and more urgent that we tackle these problems head on and aligning with PBPC makes everyone stronger.

It is becoming more and more urgent that we tackle these problems head on and aligning with PBPC makes everyone stronger.

Interested in learning more about how plant-based products contribute to a more sustainable economy? Sign up for our newsletter.